How Water Softeners Work

As rain water percolates through chalky soil/rocks it picks up calcium and mangnsium minerals. These calcium and magnesium salts (hardness) drop out of pipes especially in hot water. They stick to the surfaces forming lime scale. This blocks pipes and acts as insulation meaning boilers are inefficient and increasing heating bills. Softening water removes the hardness making the water feel silky, reducing heating bills and reducing the need for detergents.

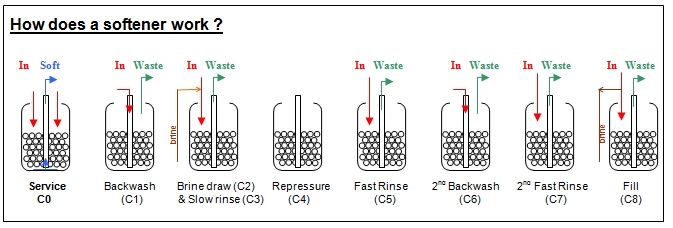

C0 In the service position hard water enters the softener flows down through the resin were the hardness is held and up through the central riser tube and out to service.

Regeneration: When the resin becomes saturated with hardness it needs to be regenerated (with salt).

C1 Backwash. Water flows from the inlet through the valve and is redirected down through the riser tube and UP through the resin. This lifts the resin and washes out any debris.

C2/C3 Brine draw and slow rinse. A salt solution is slowly fed through the resin which drives off the hardness which goes down the drain and sets up the resin for service again.

C4 Re pressure. A small wait state to allow the system to equalise pressure.C5 Fast Rinse. In the unlikely event of any brine still being in the resin this stage flushes it out.

C6/C7 2nd backwash and fast rinse . Short backwash and rinse as another safety feature to make sure all brine is cleared.

C8 Fill. A measured amount of water is fed into the brine tank to dissolve a programmed amount of salt and produce brine ready for the next regeneration.

Regeneration: When the resin becomes saturated with hardness it needs to be regenerated (with salt).

C1 Backwash. Water flows from the inlet through the valve and is redirected down through the riser tube and UP through the resin. This lifts the resin and washes out any debris.

C2/C3 Brine draw and slow rinse. A salt solution is slowly fed through the resin which drives off the hardness which goes down the drain and sets up the resin for service again.

C4 Re pressure. A small wait state to allow the system to equalise pressure.C5 Fast Rinse. In the unlikely event of any brine still being in the resin this stage flushes it out.

C6/C7 2nd backwash and fast rinse . Short backwash and rinse as another safety feature to make sure all brine is cleared.

C8 Fill. A measured amount of water is fed into the brine tank to dissolve a programmed amount of salt and produce brine ready for the next regeneration.

Calculating what size softener do I need and how much salt will it use ?

1 person uses about 140 litres of water per day

1 litre of softening resin can remove 50g hardness (CaCO3)

1 litre of resin requires 140g salt for regeneration

1 Kg of salt uses just under 3 litres of water to make a saturated brine solution

Eg 25 litre softener in Limerick when the hardness is 300mg/l (0.3g)

Capacity or water between regenerations: 25 l x 50g = 1250g/ 0.3g =4166 litres (at 160 l /day/person in Limerick= 26 man days)

4 people in a house = 6 days between regenerations.

Salt usage per regeneration: 25 l x 140g = 3500g = 3.5 Kg

Amount of brine in brine tank: 3 x salt = 10.5 litre

When sizing a system the average flow and the peak flow rate need to be taken into account. Try and size a system to run for 3 days without regenerating or a duplex for 12 hours. The average flow rate is normally 40 times the litres of resin (40BV) although peak flows are often higher. For a duplex softener a run time of 12 hours is ok as the standby system can kick in while the duty vessel is off line being regenerated.

1 person uses about 140 litres of water per day

1 litre of softening resin can remove 50g hardness (CaCO3)

1 litre of resin requires 140g salt for regeneration

1 Kg of salt uses just under 3 litres of water to make a saturated brine solution

Eg 25 litre softener in Limerick when the hardness is 300mg/l (0.3g)

Capacity or water between regenerations: 25 l x 50g = 1250g/ 0.3g =4166 litres (at 160 l /day/person in Limerick= 26 man days)

4 people in a house = 6 days between regenerations.

Salt usage per regeneration: 25 l x 140g = 3500g = 3.5 Kg

Amount of brine in brine tank: 3 x salt = 10.5 litre

When sizing a system the average flow and the peak flow rate need to be taken into account. Try and size a system to run for 3 days without regenerating or a duplex for 12 hours. The average flow rate is normally 40 times the litres of resin (40BV) although peak flows are often higher. For a duplex softener a run time of 12 hours is ok as the standby system can kick in while the duty vessel is off line being regenerated.