Vessels and distribution

|

All of their vessels have a maximum working pressure of 10 bar and a design lifetime of 250,000 cycles from 0 to 10 bar. The latest generation of vessels is made using an integral polyethylene liner and a high strength outer of continuous glass filament and epoxy resin. The polyethylene liner ensures that water quality is maintained in critical applications while allowing the use of a variety of regenerants including salt, acids and caustic soda. Many vessels are WRAS listed.

| |||

|

Composite vessels: 2.5" top hole>

Size: 6 to 13" diameter height: up to 54" Volume: up to 103 litres Temperature: <50C Working pressure: <10 bar Up to 10 x 35" with or without base Above 10 x 35" with base Temperature: <50C |

Composite vessels: 4" top hole or top/bottom hole

Size: 14 to 24" diameter top hole Size: 14 to 36" diameter top/bot hol height: up to 72" Volume: 92 to 450 l (top) 1084 l (top/bot) Temperature: <50C Working pressure: <10 bar |

|

Dome hole vessels

These vessels allow topping up/inspection of media through a dome hole without taking off the valve (eg pH correction systems) Size: 10 x 54"(61 l) and 13 x 54" (103 l) Temperature: <50C Working pressure: <10 bar |

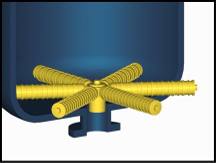

Distribution systems

Distribution systems (risers/laterals) for domestic softeners through to industrial filtration/softeners) |